Year

2018

Amphit Products

-Oxygen Scavenger (Hydrazine Based)

-Oxygen Scavenger (Catalysed Sulphite Based)

-Oxygen Scavenger (Hydracarbized )

-Oxygen Scavenger (DEHA)

-Alkalinity Builder + Sludge Conditioner

-pH Booster (Organic)

-Multi Amine(Condensate Neutralizer)

-Amine Treatment (single chemical) for boiler

-Antiscalant-Boiler Water(Powder)

-Antiscalant- Boiler Water(Liquid)

-Steam Condensate Conditioner

Amphit Products

-Scale & Corrosion Inhibitor % Bio-Dispersant

-Anti-Foulant

-Antiscalant

-DG. Coolant

-Non-Oxidizing Biocide

-Corrosion Inhibitor

-Pre-Clinic & Passivation Chemical

BOILER WATER TREATMENT

Boiler is a steam generation unit. This steam is used in various operations like heating, power generation, etc. Water used in boiler may contain many types of impurities that may harm the system. Hence internal treatment of boiler water is necessary.

Boiler is a steam generation unit. Water used in boiler may contain many types of impurities that may harm the system. Hence internal treatment of boiler water is necessary. AMPHITRITE INDUSTRIES provides technically advanced boiler water treatment chemicals have been scientifically formulated to improve the operation and maintenance of industrial boiler systems and steam generation plant by proactively managing the problems associated with the use of water including scale formation, metallic corrosion, boiler water carryover and sludge deposition. AMPHITTM of products to give preventive measures to minimize the problems through proper treatment with different chemistries.

COOLING WATER TREATMENT

Cooling tower is a heat removal device that uses water to transfer process, waste heat into the atmosphere. Likewise, an industrial cooling tower operates on the principle of removing heat from water by evaporating a small portion of water that is recirculated through the unit. Cooling towers are simple heat exchangers where water serves a medium to exchange heat. Since large quantity of water is required hence it is very difficult for the pre-treatment of water. So water is used as it is due to the presence of impurities in water cooling tower also have some regular problems.

Cooling tower water treatment system is an arrangement of technologies that remove damaging impurities from. Your cooling tower feed water, circulation water, and or blowdown. Without the proper chemical treatment program, a cooling tower may begin to lose efficiency as a result of corrosion, scale deposition, and biofilm growth. Treatment programs consist of Inhibitors to protect against scale and corrosion and biocides to protect against microbial growth and biofilm. AMPHITRITE INDUSTRIES provides AMPHIT range of products to protect cooling towers from any harm.

Manufacturing Chemicals

Manufacturing boiler water and cooling water treatment chemicals involves a specialized process of synthesis and formulation to create customized products that meet the specific requirements of different industries. These chemicals are used to prevent scale formation, corrosion, and microbiological growth in industrial water systems, such as boilers and cooling towers.The first step in manufacturing these chemicals is to identify the specific requirements of the water system and the intended end-use.The next step is to synthesize the chemical compounds and formulate them into a liquid or powder form. The final product must meet strict regulatory and environmental standards.

Overall, the manufacturing of boiler water and cooling water treatment chemicals is a complex process that requires careful attention to detail and a commitment to quality and sustainability. By creating high-quality, sustainable products, Amphit helps to ensure the efficient and effective operation of industrial water systems while minimizing their impact on the environment.

Sustainable Chemicals

As sustainability becomes increasingly important in the industry, we are always working to develop more environmentally friendly solutions. This includes the use of renewable resources, reducing waste and energy consumption, and creating products that are biodegradable and safe for the environment.

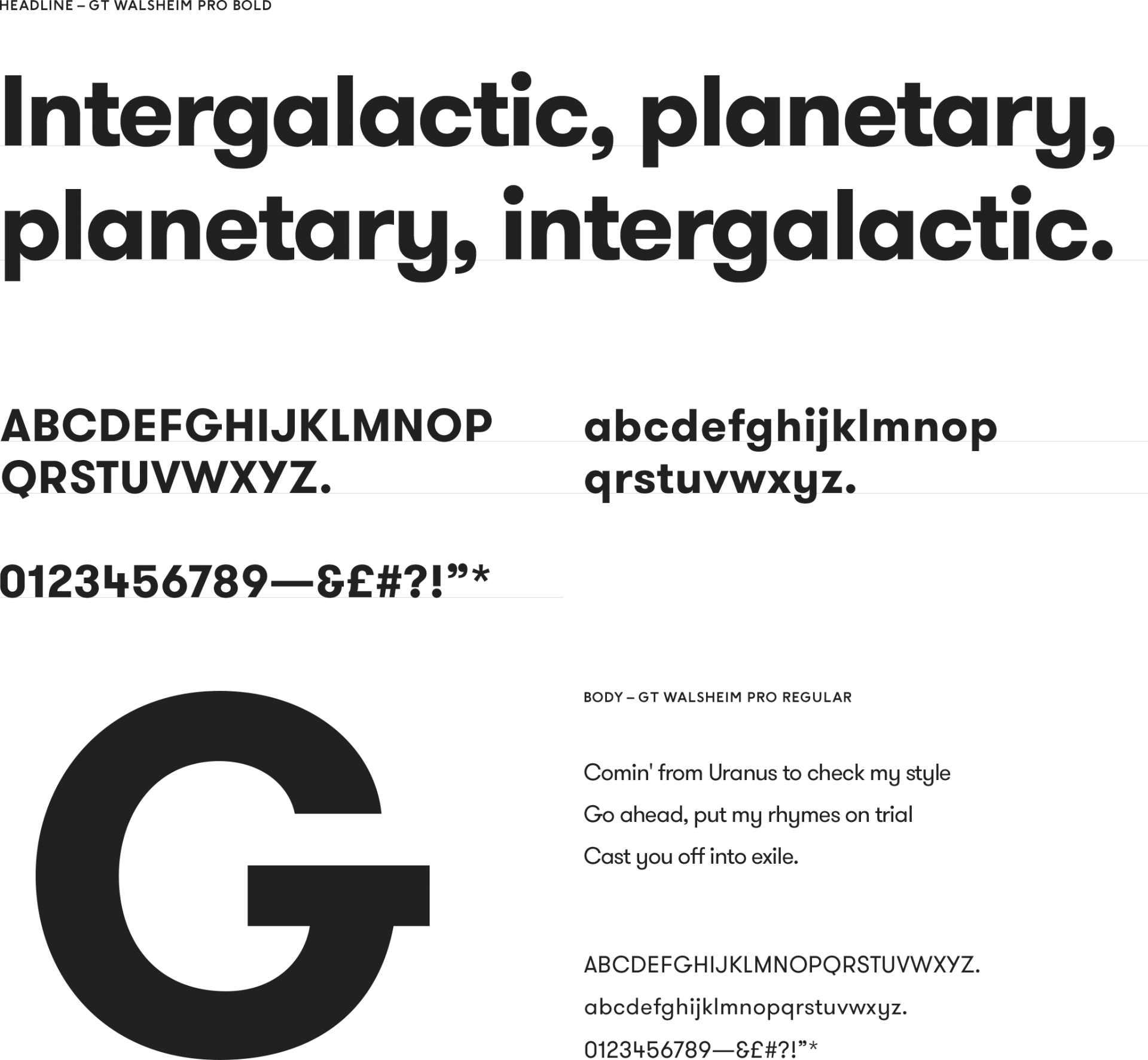

Typography